Driving Efficiency with Smart Energy Audit, Monitoring, and Controls. P.O.Box 20898 Al Qusais Dubai, UAE

Discover how Smart Maintenance by Nashat Energy combines predictive, preventive, and condition-based maintenance to achieve zero downtime and energy efficiency.

and condition-based maintenance to achieve zero downtime and energy efficiency.

It often starts with a small noise — a motor running harder than it should. Then, an unexpected shutdown. The result: lost hours, wasted energy, and higher costs.

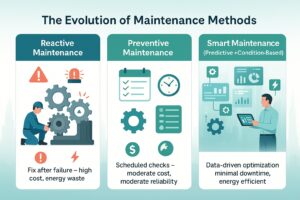

Across the UAE and GCC, many facilities still depend on reactive or fixed-schedule maintenance. In energy-intensive environments—factories, hospitals, hotels, and district cooling plants—these breakdowns cost more than just repairs. They increase energy waste, disrupt operations, and reduce equipment life.

That’s why leading businesses are shifting to Smart Maintenance—a strategy that uses predictive insights to keep systems efficient, reliable, and sustainable.

Smart Maintenance is the next evolution of maintenance management.

It combines multiple strategies under one intelligent framework:

At Nashat Energy, Smart Maintenance integrates all three—powered by IoT, cloud analytics, and energy monitoring—to deliver continuous reliability with measurable energy savings.

Our Smart Maintenance system continuously monitors your critical assets—chillers, pumps, HVAC units, and electromechanical systems—through IoT sensors and data analytics.

This approach turns maintenance from a reactive task into a predictive, proactive, and data-driven strategy.

1. Zero Unplanned Downtime

Our clients reduce downtime by up to 50% using predictive alerts and KPI scheduling that align with planned maintenance windows.

2. Measurable Energy Savings

Well-maintained systems consume less energy. Continuous monitoring identifies inefficiencies early—resulting in 10–15% lower energy consumption across maintained assets.

3. Lower Maintenance Costs

Smart Maintenance reduces unnecessary servicing and part replacements by performing maintenance only when it’s needed—cutting total maintenance costs by 20–40%.

4. Extended Equipment Lifespan

Real-time monitoring minimizes stress on critical systems, prolonging asset life and avoiding premature replacements.

5. Enhanced Reliability & Safety

Predictive analytics reduce emergency breakdowns, ensuring safer operations and more stable facility performance.

🏢 Commercial Buildings

Hotels, offices, malls, and schools use Smart Maintenance to monitor HVAC, lighting, and elevators—improving comfort, uptime, and energy efficiency.

🏭 Industrial Facilities

Factories, logistics hubs, and district cooling plants rely on IoT-driven monitoring of chillers, compressors, pumps, and air handling units for maximum reliability and cost control.

🏠 Residential Complexes

Building managers monitor cooling systems, water pumps, and appliances through Smart Maintenance dashboards—preventing failures before they impact residents.

| sect | Predictive Maintenance | Smart Maintenance (Nashatx) |

|---|---|---|

| Focus | Predict when a failure will occur | Combine predictive + condition-based + preventive + energy monitoring |

| Data Source | Equipment sensors only | Sensors + energy + environmental data |

| Platform | Standalone software | Integrated with KPI-based PPM Planner |

| Outcome | Reduced breakdowns | Improved reliability and energy sustainability |

Many people search for Predictive Maintenance, Condition-Based Maintenance, or Proactive Maintenance — at Nashat Energy, Smart Maintenance covers them all.

Smart Maintenance is part of our Comprehensive Energy Management Solutions.

By linking maintenance data with energy KPIs, we identify both mechanical and operational inefficiencies in real time.

For example:

This integration turns maintenance into a continuous improvement cycle for energy performance.

These results translate into smoother operations, sustainability credits, and measurable financial savings.

Our Smart Maintenance solutions are built for the GCC’s unique challenges—high temperatures, heavy HVAC loads, and energy-intensive facilities.

We don’t just monitor assets; we help you measure, predict, and improve.

Ready to move from reactive to smart?

Let’s design a maintenance strategy that guarantees uptime and energy performance.

📞 Contact Nashat Energy today to implement Smart Maintenance for your facility and unlock data-drive

n reliability and sustainability.

Q1: What is Smart Maintenance?

Smart Maintenance combines predictive, preventive, and condition-based maintenance using IoT and analytics to prevent failures and save energy.

Q2: Is Smart Maintenance the same as Predictive Maintenance?

Predictive maintenance is one part of Smart Maintenance. Nashatx integrates predictive, condition-based, and preventive maintenance with energy data for smarter decisions.

Q3: How does Smart Maintenance reduce energy costs?

By detecting performance drops and inefficiencies early, Smart Maintenance keeps assets operating efficiently—reducing energy waste by up to 15%.

Q4: What industries benefit from Smart Maintenance in the UAE?

Industrial, commercial, and residential sectors benefit most—especially facilities with HVAC, district cooling, and energy-critical systems.

Q5: How can I start implementing Smart Maintenance?

Contact Nashat Energy to assess your current maintenance and energy performance. We’ll build a roadmap tailored to your assets, KPIs, and sustainability goals.