Driving Efficiency with Smart Energy Audit, Monitoring, and Controls. Dubai, United Arab Emirates

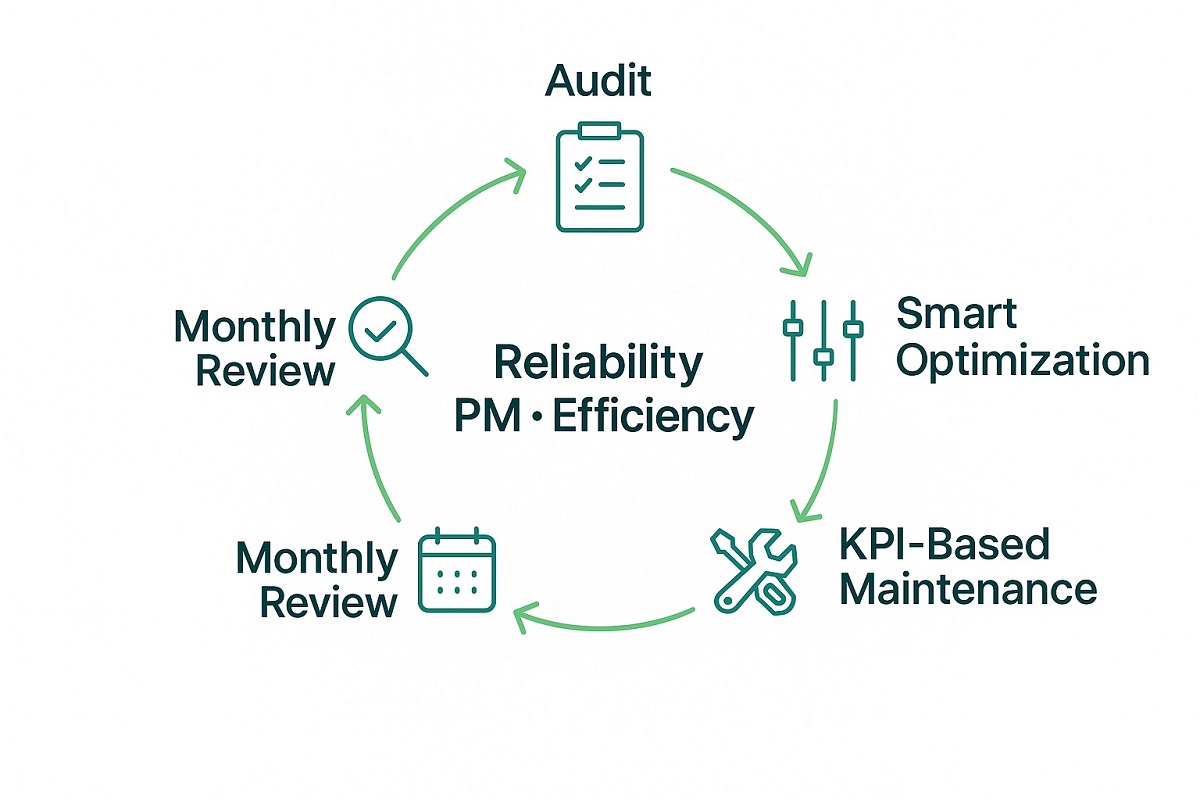

At Nashat Energy, KPI-driven management turns energy data into measurable performance. We focus on three core metrics—Reliability, PM Compliance, and Efficiency—to cut costs, extend equipment life, and sustain uptime.

Each KPI tells a clear story:

Together, they form a performance loop powered by Energy Audits, Smart Optimization, and KPI-Based Asset Maintenance Planning—delivering 15–30% savings and long-term operational stability.

High energy bills persist even in modern facilities because most teams lack visibility.

With Nashat Energy, KPIs become the heartbeat of operations:

Keeps critical systems running and stable. We track uptime and restore times so minor issues never grow into costly downtime.

Ensures preventive maintenance happens on time, not “when possible.” Discipline here protects reliability and prevents performance drift.

Confirms your building or plant is running lean—optimizing chiller, HVAC, and system performance so real savings appear on your utility bill.

Week 1: Data pull and KPI baseline setup

Week 2: Smart optimization and schedule tuning

Week 3: KPI-triggered maintenance templates go live

Week 4: First monthly KPI review and next-step roadmap

CTA: Book your KPI Strategy Workshop today and get your first 90-day efficiency plan from Nashat Energy.