Driving Efficiency with Smart Energy Audit, Monitoring, and Controls. P.O.Box 20898 Al Qusais Dubai, UAE

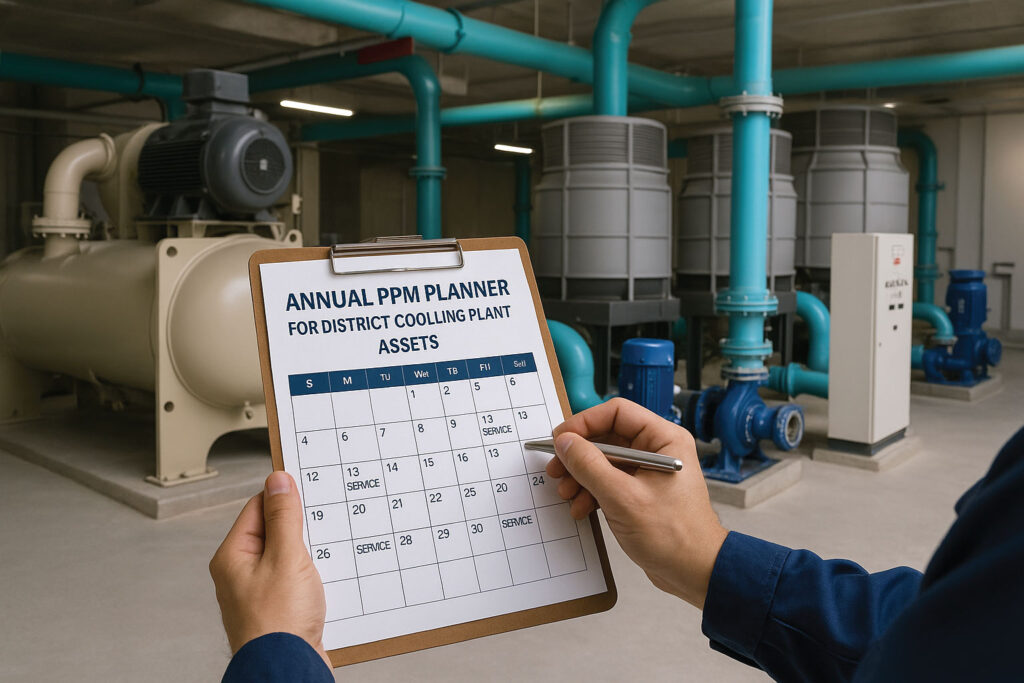

PPM Planner

Our KPI-based Preventive Planned Maintenance (PPM) Planner revolutionized the client’s district cooling plant operations by minimizing equipment failures, extending asset life, and reducing unplanned shutdowns. Through proactive asset management, the solution delivered 30% annual maintenance cost savings, significantly improved plant uptime, and avoided major breakdowns—ensuring continuous availability and substantial reductions in repair, replacement, and manpower expenses.

Before implementing our PPM Planner, the district cooling plant faced frequent equipment failures, unplanned shutdowns, and high maintenance costs. The lack of a structured maintenance schedule led to inefficiencies and increased the risk of critical failures, jeopardizing plant availability and reliability.

We designed and implemented a comprehensive, KPI-based PPM Planner and Schedule tailored to the client’s district cooling equipment. Key components included:

✅ Daily Job Assignment: A full-year schedule assigning specific PPM tasks for each operational day, aligned with equipment criticality and KPI thresholds.

✅ KPI Driven Prioritization: Maintenance tasks prioritized based on asset performance metrics and risk profiles, ensuring critical components receive timely attention.

✅ Flexible Task Selection: The ability to refine daily schedules by selecting tasks based on available manpower, shifting priorities dynamically without compromising coverage.

✅ Real Time Monitoring Integration: Dashboards tracking task completion, failure rates, and maintenance compliance to facilitate continuous improvement.

Optimized HVAC systems consistently reduce overall energy consumption through strategic upgrades, smart controls, and precise calibrations—translating into immediate cost savings.

Refine performance by calibrating equipment, upgrading control systems, and implementing smart diagnostics, ensuring peak performance, optimized throughput, and waste reduction.

Enhance equipment longevity with proactive maintenance strategies, automated monitoring, and scheduled servicing—resulting in lower repair expenses and extended asset lifespan.